Topo Designs

Topo Designs

Topo Designs crafts functional gear and accessories that bridge the gap between the outdoors and urban environments. Suitable for hiking, biking, fishing, traveling, EDC and more, all Topo Designs gear is handmade in Colorado, USA.

Visit Topo Designs-

The Best Gym Bags for Every Type of Exerciser in 2022

Historically, gym bags have been horrible, generic and saggy excuses for carry – but there’s been... Read more

-

The Best ‘Made in the USA’ Backpack Brands of 2022

There are great American brands making awesome carry gear. And on the flip side, there are... Read more

-

Best Travel Luggage Champion 2020

Our Best Travel Luggage 2020 has to soar high on long-lasting durability, organization and access, and... Read more

-

CARRY AWARDS 8

Top 5: Best Travel Luggage 2020

Best Travel Luggage, what an awesome idea and award… until you throw in the year that... Read more

-

CARRY AWARDS 8

Carry Awards VIII: Best Travel Luggage

No two trips are the same. Some trips require sophisticated style, from chic urban getaways to... Read more

-

These are the Brands, Retailers and Publishers Standing Against Racism

Here at Carryology, we have many goals that we set for ourselves. And one of those... Read more

-

10 Essentials to Pack in Your City Laptop Backpack

I still remember the start of my freshman year of college. The process of getting my... Read more

-

Best New Gear: April 2019

April welcomed in a wealth of enticing new offerings to suit travelers, EDC enthusiasts and outdoor... Read more

-

Carry Guide: Find the Best Travel Backpack for You

So here’s the thing. There’s no ultimate best travel backpack to suit everyone at any time,... Read more

-

The 20 Best Laptop Backpacks Under $125

Laptops are a pretty common addition to carry setups these days. Whether you’re commuting with one... Read more

-

Topo Designs Travel Bag 40L: Video Review

One bag to carry a week’s worth of vacation gear? The challenge was set for the Topo... Read more

-

Our Favorite Organization Pouches for EDC Right Now

The little things are important in life. And that holds true for your EDC too. Those... Read more

-

The Best ‘Back to School’ Backpacks for Everyday Carry 2018

When it’s time to get back to school, a good backpack is an important addition to... Read more

-

Best New Gear: July 2018

Furoshiki-inspired carry, rugged dry duffels and adaptable travel backpacks step into the spotlight as we check... Read more

-

Best New Gear: April 2018

From camera bags to collaborations, and carrying urban essentials to outdoor adventure supplies, April has welcomed... Read more

-

Best New Gear: March 2018

Convertible bags, durable camera protection, sleek urban tech carry and practical trail packs are just some... Read more

-

The 30 Best Dopp Kits for Traveling

You’ve got the tickets sorted. Accommodation booked. Packing pretty much done. There’s just one final piece... Read more

-

The Ultimate Guide to the World’s Best Duffel Bags

Duffel bags are commonly thought of as the workhorses of the carry world. Durable, versatile gear... Read more

-

DEALS!

Topo Designs: Exclusive Readership Deal

Our friends over at Topo Designs make some of the best carry gear around. What makes... Read more

-

15 Essential Gifts for the Traveler

With the holiday season approaching it’s a prime time to enjoy some downtime away from home.... Read more

-

READERSHIP EXCLUSIVE

Exclusive Release: Topo Designs x Carryology Klettersack Backpack

This was so difficult to keep secret for several months. But now, ladies and gentlemen, we... Read more

-

SNEAK PEEK

The First Ever Carryology Collab: a Story of Sub-Zero Hikes, Geek Speak and Butterflies

For months now, we’ve been sharing geek speak in whispers, watching craftsmen and makers maintain the... Read more

-

Best New Gear: October 2017

From tech protection to all-in-one EDC, October has welcomed a host of great new gear onto... Read more

-

Best New Gear: September 2017

From lightweight travel bags to slim and minimalist EDC, the past month has seen a host... Read more

-

Our Favorite Bags Made from CORDURA

CORDURA® fabrics are synonymous with durability and reliability – ideal traits when you want to build bags... Read more

-

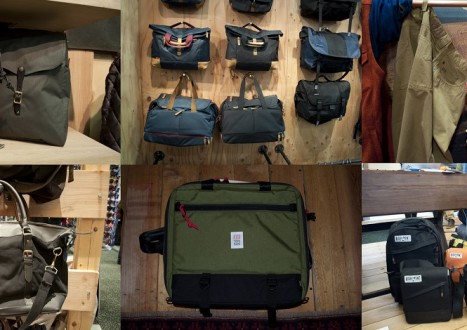

Outdoor Retailer Summer Market 2017 :: Recap Part I

It was a bittersweet moment as I flew into the valley, knowing this would be the... Read more

-

The Best Backpack Deals from REI

REI are one of the world’s best carry retailers. And when they clear out stock and start... Read more

-

Best Check-In Finalists – The Fifth Annual Carry Awards

Business or pleasure. Outdoor adventures or taxi-to-hotel trips. Our Best Check-In Finalists cater to a range of... Read more

-

Best Work Messenger Finalists – The Fifth Annual Carry Awards

Easy accessibility, comfort on the go, a nod to style, and the flexibility to move beyond... Read more

-

The Best Backpacks for Everyday Carry

Choosing an EDC backpack deserves careful consideration. After all, it’s going to be your daily companion... Read more

-

Top 10 Back To Study Bags

Having a study bag fail you is a hard lesson to learn. If you want to... Read more

-

Topo Designs Mountain Duffel

Having your gear dig into you can make carrying a pain. But the Topo Designs Mountain... Read more

-

The Ultimate Camping Gift Guide

Need gift ideas for a special someone who loves camping and the outdoors? Get inspired and... Read more

-

Waterproof vs Water Resistant. What Do I Need?

There are few things more frustrating than arriving somewhere and realizing your gear is soaked through.... Read more

-

Huckberry Presents :: Best US-Made Duffels

Huckberry know US-Made; it’s kinda their thing. And they get away on more weekends and haul... Read more

-

Outdoor Retailer Summer 2016 :: Recap Part III

On the last and final day of Outdoor Retailer Summer 2016, we spent the second half... Read more

-

Best Bags for Architects

This piece was researched and written by award-winning architect, educator and critic Graeme Nicholls. As an... Read more

-

Topo Designs x Uncrate Rover Pack :: Video Review

Chase Reeves dives into the details in his signature fun style as he takes the Topo... Read more

-

Introducing Our Carryology Concept Store

Oh yes. We’re doing it! That’s right, we’re lifting Carryology beyond the digital world, and bringing... Read more

-

Packing List of a Digital Nomad

There’s something undeniably alluring about a road trip – the freedom of the open road, embracing... Read more

-

The Topo Designs x Woolrich Collaboration

On the tail of Topo Designs’ third collaboration with the venerable Woolrich Woolen Mills, Frank Sedlar... Read more

-

Topo Designs Duffel

Solid construction, simple design and Topo’s distinct aesthetic style make this a duffel that will stand... Read more

-

Buyer’s Guide :: Best Weekender Duffels

Whether you’re heading off on a spur-of-the-moment weekend getaway, seeking adventure round every bend with a... Read more

-

Bag Collectors :: Greg Davis

Greg Davis can be considered somewhat of an accidental bag collector. Like many carry collections, his... Read more

-

Outdoor Retailer Summer 2015 :: Recap Part I

Bursting from downtown Salt Lake City, Utah another rendition of Outdoor Retailer has hit. As usual,... Read more

-

A New Initiative :: Send us Your Carry ID!!

What we carry – like our book or music collection – identifies who we are. Every small,... Read more

-

Buyer’s Guide :: Best Heritage Backpacks

Heritage is a trend that has been sweeping across the carry world in recent years. Everywhere... Read more

-

Design Heads :: Jedd Rose (Topo Designs)

It must feel pretty great being a co-founder and Creative Director of one of the most... Read more

-

The Best Briefcases for Dapper Professionals

Having the right briefcase is one of the best ways to say you mean business without... Read more

-

Buyer’s Guide: Best Travel Backpacks

Celebrating the release of our beta Buyer’s Guide we’re dishing up the categories in sweet, easily... Read more

-

Outdoor Retailer :: Winter Market Recap

Once again, and this time five members strong, Carryology converged upon Outdoor Retailer to unearth the... Read more

-

TOPO Designs Travel Bag

At Carryology, we love all sorts of bags. But when somebody releases a bag with modular... Read more

-

TOPO Designs Klettersack 22L

Topo’s classic. An ideal travel companion, workmate or pack mule for the daily hike in the... Read more

-

TOPO Designs Daypack

Your school backpack grown up, while Topo Daypack has a simple two compartment design, the craftsmanship... Read more

-

TOPO Designs Klettersack 15L

Topo’s classic. An ideal travel companion, workmate or pack mule for the daily hike in the... Read more

-

Road Tests :: Topo Designs Rover Pack

When Topo Designs, a company founded by three outdoor enthusiasts and friends, entered the industry in... Read more

-

Best Carry Accessory Finalists – The Second Annual Carry Awards

Accessories have been described as things that contribute to or aid in an activity or process... Read more

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews